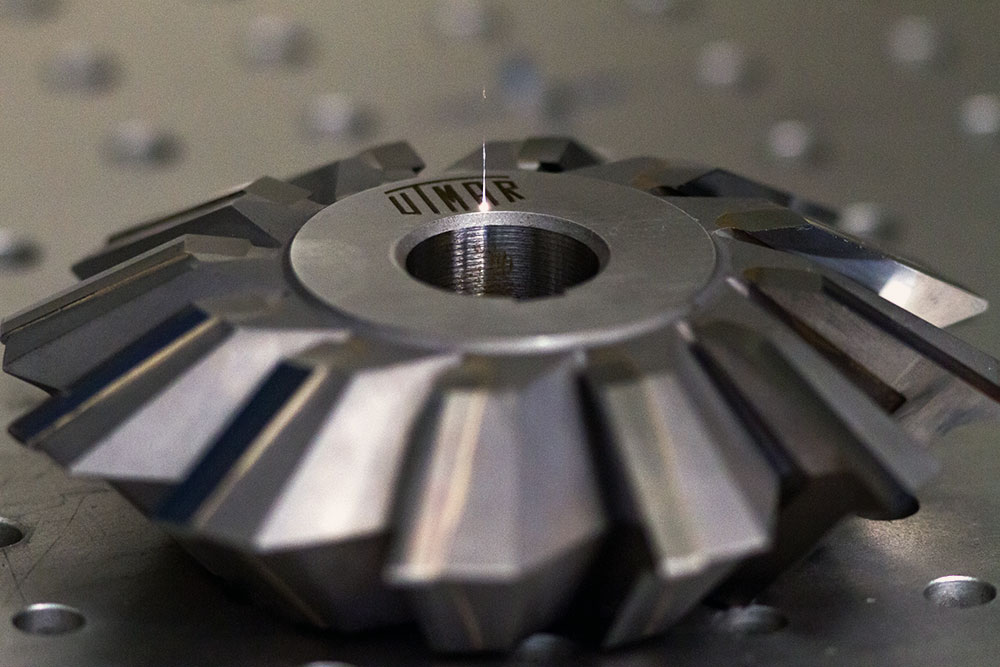

SHARPENING special tools

The company provides a complete regrinding service, which covers all types of products: milling cutters, drills and reamers, tools, as well as inserts and cusps.

With sharpening, the company can completely regenerate any tool, whether it is hard metal, HSS steel or PCD diamond. The company can recommend the best coating to cover remanufactured tools to improve their useful life. All the regrinding tools are laser marked with a customer identification code to prevent them getting mixed up with others.